Why Machining at Lucent Mfg.?

Your China Custom Parts Shop.

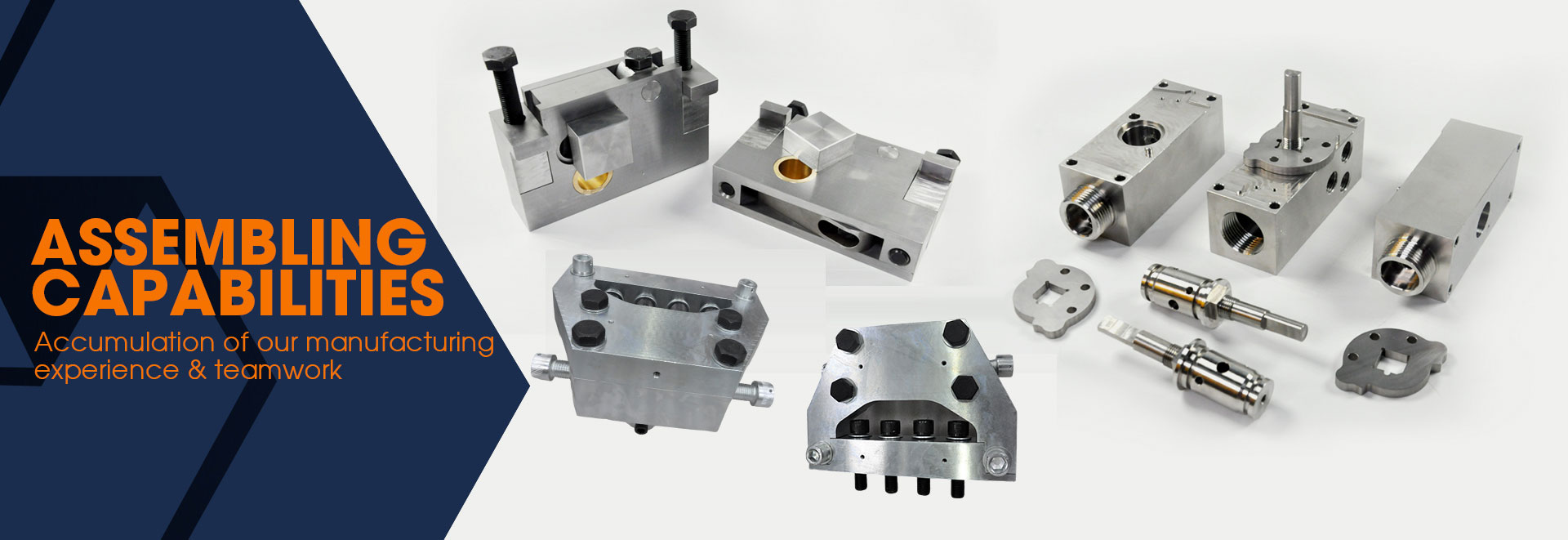

Capabilities for Custom Parts

About Lucent

Lucent Ind. Manufacturing, Ltd. is Hong Kong based group company with all manufacturing facilities in Guangdong, China – Pearl River Delta area. We are specialized in manufacturing custom-made precision Machining Components, Casting Parts, Hardware, Plastic Mold Design & Build and also Production.

We offer a wide range of manufacturing solutions, including machining, casting, forging, stamping and molding. Our engineering team has rich experience in working for many Fortune 500 companies (ITW, Electrolus, Caterpillar etc.)

We have highly skilled and experienced engineers who work collaboratively on every project. They will submit detailed manufacturing solution regarding different product’s characteristics. At each manufacturing stage, our engineers work with the operation team to ensure quality control procedures are properly implemented and the specification is 100% in compliance.

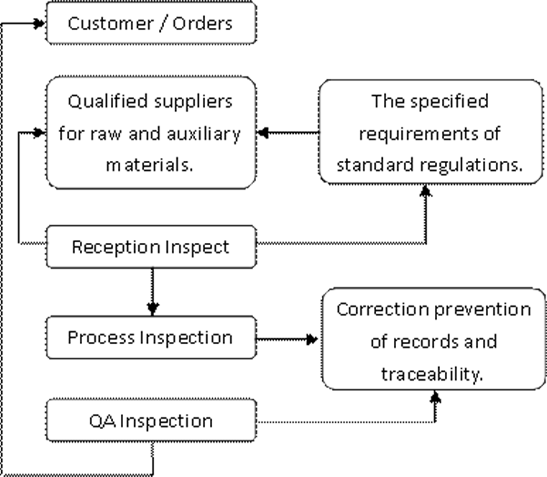

We have one quality control team which is built up by rich experienced QC & QA. They will monitor each process of production. Each component or part will go through our QA for final inspection and testing. Make sure every product is under customer’s requirement before reaching customers.

Our focus is to close the gap and provide lower cost manufacturing throughout the world. Sourcing your parts with Lucent MFG. is the closest thing to running your own manufacturing facility in China. We offer extreme flexibility for you and your project needs.

Lucent MFG. will provide you with the following benefits and advantages:

·More saving on manufacturing cost.

·State-of-the-art manufacturing facilities.

·On site manufacturing supervision for quality control.

·Bilingual engineers reporting on your project.

·Reasonable short lead time.

Precision Machining

We are specialized in producing different type of precision parts for our customers. The highest tolerance of the part can be up to +/-0.0002” (+/-0.005mm). No matter the parts are ordered in low or high volume, we can finish them in a reasonable short lead time.

The parts will be inspected strictly in their progress so that all of them can meet customers’ requirements. The parts are widely used for fixtures, automobiles, equipments etc.

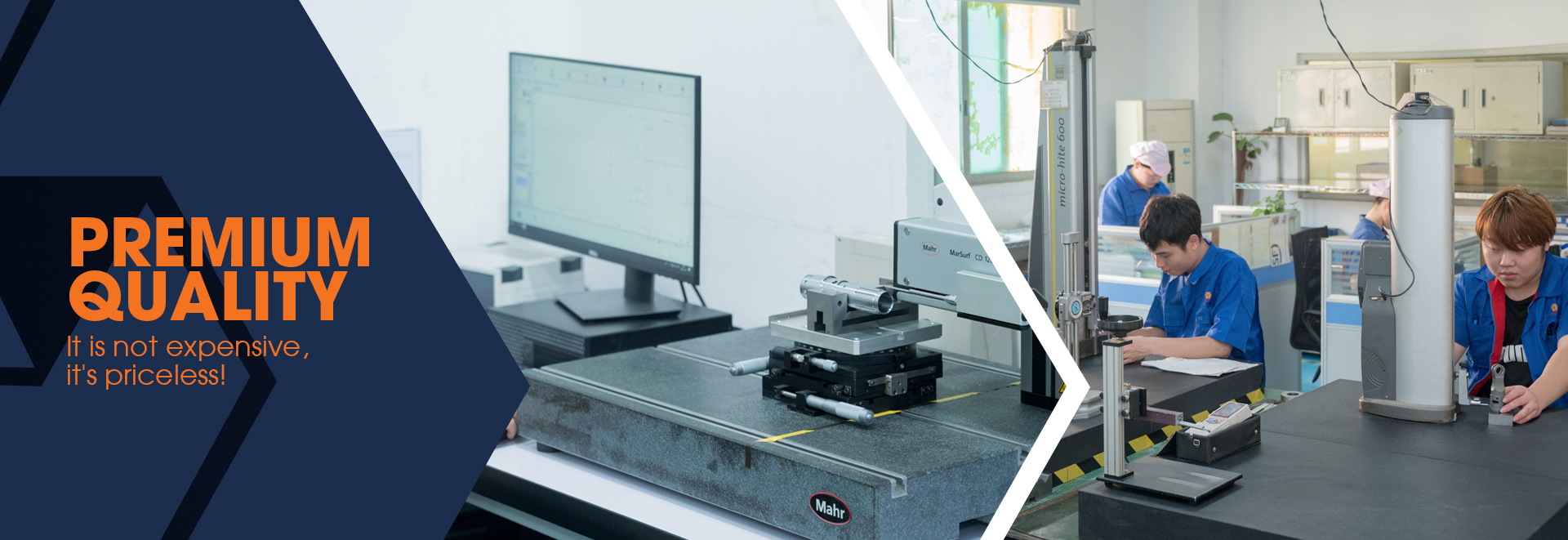

Quality

Quality is the life of our company. In order to provide our clients with high quality products, we have purchased advanced inspection equipments, introduced in ISO9001 quality management and build a strict quality guarantee system. The quality management system philosophy has run through the whole workflow from the design to after-sales service.

Testimonials

Customized Parts Department

Bossard (Switzerland)

Quality Engineering,

BD Biosciences

Corporate Purchasing,

COESIA Group

Design Engineer Director,

ITW Dynatec

Fasteners Buyer,

Foxconn

One of strategic source to achieve our quality and quick turn around parts needs

We are very satisfied about the result and experience working with Lucent.

From simple parts vendor to our list of superior suppliers to serve a number subsidiers of our group.

Thanks Lucent Fellows, for your rapid response in reverse engineering. prototype and low-volume production, more new projects send to your way!

Well done! Thanks for the long-term efforts in the high strength bolt experiment, the related product has been put into mass production smoothly.